Low-energy buildings

Ever since CAT first started, one of our main aims has been to construct low energy buildings. Reducing heating demand is vital when building or renovating, because it’s then much easier to meet our future energy needs.

Minimising Energy Use

In an average house, about two-thirds of all energy use is for heating. If building a new home you have an ideal opportunity to go beyond the minimum required insulation levels. Even with a renovation project there is often the opportunity to insulate to very high standards.

Minimising heat loss will lead to to reduced carbon emissions as well as lower fuel bills. Spending a little extra on insulation can lead to big fuel savings over time. It’s possible to reduce your impact still further by using renewable energy heating options like a heat pump or biomass boiler.

To achieve low energy buildings, the main considerations are high standards of insulation & draught-proofing, and adequate ventilation without heat loss.

Good-quality detailing around doors and windows will minimise draughts and heat loss. Argon-filled double-glazing with a ‘low-e’ coating is the most efficient type of pane. Timber framed windows have a much lower environmental impact than those using uPVC or aluminium.

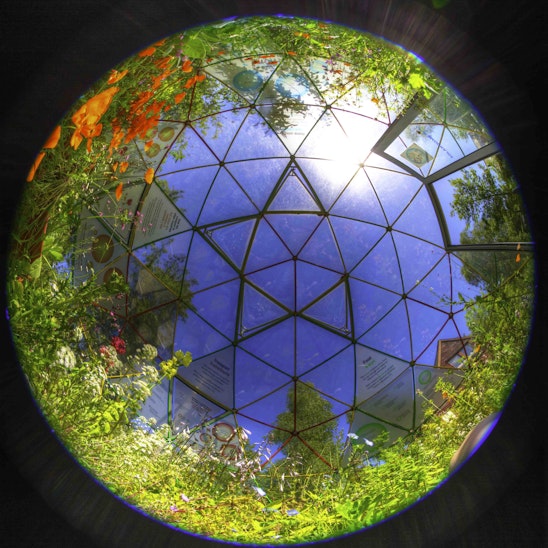

In our mild climate, it is usually appropriate to have some form of passive ventilation, with warm air rising through the building, and replacement fresh air coming ideally through a ‘buffer’ space, such as a south-facing conservatory.

Underfloor heating gives a comfortable, even heat and is also efficient – running at about 35°C, rather than the 60 to 70°C of conventional radiators.

A low-energy house can meet some heating needs and create a pleasant living space with ‘passive solar’ design methods. These make the best use of available sunlight, by careful orientation of windows and doors.

Embodied Energy & Pollution

Once the energy needed in the day-to-day life of a building has been minimised, then the energy used in construction becomes a bigger proportion of the building’s overall energy use. So it makes sense when planning an energy efficient house to make careful choices about the materials used.

The ‘embodied energy’ of materials includes the energy used to extract, manufacture, and transport all the materials used. Another way of assessing materials is the life-cycle impact, including other types of pollution and adverse impacts.

Harvesting and processing timber uses a small amount of energy and with local timber the embodied energy is even lower. You can reduce it still further by using reclaimed timber.

Some low energy buildings will require particular materials and it’s a matter of balancing the benefits of a method against its impact. For example, a home using passive solar design principles could have a concrete floor for absorbing and store solar energy, and the energy gain from this may outweigh the impact of the materials.

Because of the high temperature to which it must be heated, and the associated chemical reaction, emissions of carbon dioxide from cement manufacture and use are very high. Alternatives like earth or hempcrete are available, which have a lower impact and are also breathable. Natural building materials can help to create healthier buildings.

PVC (polyvinyl chloride) is versatile and widely used, but creates pollution in both manufacture and disposal. Alternatives such as polybutylene and polyethylene have a much lower impact and are recyclable.

Further Information

See the related questions below for more details. CAT runs many short courses on building techniques. We also offer workshops to visiting groups. Our online shop also stocks several comprehensive books on environmental building.

Finding eco-builders

The AECB promotes sustainable building and retrofit, and you can find eco-builders using their directory of members. Or see the Passivhaus Trust member listings. Another listing site for green builders is the Green Register.

Related Questions

What is a U-value, and what is thermal conductivity?The U-value is a measure of how many watts (representing the rate of flow of energy) pass through one square metre (m²) of a construction detail (such as a wall) for every degree difference in temperature between the inside and the outside. Temperature is measured in kelvin, and 1K = 1°C (degree centigrade).

As an example, a U-value of 6.0W/m²K for a single glazed window means that six watts will be escaping through each square metre of glass when the temperature difference is one degree. If it is 20°C in the house and 0°C outside, then the heat loss is 20 x 6 = 120 watts per square metre.

U-values are generally used to describe the thermal performance (heat loss) for a section of construction that involves several materials – such as a wall made up of timber, insulation, board & render.

Thermal conductivity

For individual materials, such as a type of insulation, you’ll come across the term ‘thermal conductivity’, also known as a k-value or λ-value (lambda). This is the rate at which heat flows through a particular material, and good insulation will have a low thermal conductivity. It is measured in watts (heat flow) per metre (depth of material) per degree difference (inside to outside), so the unit is W/mK.

Most natural insulation materials (hemp, wool, recycled paper or textile) will have a thermal conductivity of about 0.035 to 0.040 W/mK, which is similar to the performance of conventional mineral wool insulation. Foil-backed plastic foam insulation boards are slightly better, with thermal conductivity about 0.023 W/mK. So about 100mm of the plastic foam board will give equivalent insulation value to about 150mm of the various woolly types.

There are basically three different types of insulation material:

- Organic – those derived from natural vegetation or similar renewable sources, which tend to require a low energy use in manufacture (a low ‘embodied energy’). Examples are sheep’s wool, cellulose, cork, wood fibre, and hemp.

- Inorganic – derived from naturally occurring minerals which are non-renewable but plentiful at source. Likely to have a higher embodied energy than organic materials. Examples are mineral/glass fibre, perlite and vermiculite (from volcanic rock) and rigid foamed glass.

- Fossil organic – derived by chemical processes from fossilised vegetation (oil) – a finite resource. Fossil organic insulation materials such as expanded polystyrene and polyisocyanurate or phenolic foam are highly processed, resulting in a high embodied energy.

Which is best?

If possible it is better to choose insulation materials that have not been heavily processed as this will reduce the carbon footprint and environmental impact of your home. But it is far better to install cheaper inorganic or fossil organic materials with the right physical properties and a low thermal conductivity than to install nothing at all.

In many cases, organic insulation material can be applied instead of inorganic or fossil organic, but there are exceptions. For example, there is not an organic insulation material suitable for cavity wall insulation.

Think also about the ease of installation. Loose fill insulation is quick to put in in lofts, but cannot be DIY installed in anything other than a flat place. Rigid boards and batts will come in certain sizes, but need to be cut to shape if you have some unusual spaces. Some materials can be cut with a knife, but a few will need a saw. Some mineral wool now comes in a thin foil or plastic wrap, to protect from the fibres. You should still wear a face mask when installing any type of installation, as small fibres of any kind are best not inhaled.

Foundations are designed to spread the load of the building over a wide area to prevent sinkage. The base needs to be below the frost line (usually 750mm), free of organic matter that could rot, and away from trees.

The environmental impact of concrete use can be minimized by installing pad or strip foundations and using recycled rubble as general fill. The cement in concrete can be avoided by using hydraulic lime as the binder. Adding large aggregate to bulk out the concrete saves cement. Recycled aggregate, such as crushed waste concrete, can be reused with hardly any impact on strength. You can substitute up to 50% of the cement with pulverised fuel ash (PFA), a waste from power stations, or with GGBFS (ground granulated blast furnace slag), a byproduct of the steel and iron industry.

CAT ecobuilding experts have given the following preference list for foundations (from most to least preferable). You could also seek advice from a local eco-builder or architect by looking through the AECB listings or the Green Register.

Masonry construction:

- Local stone foundation wall; DPCs/membranes of recycled polythene or bitumen; land drains around the house perimeter; minimise thermal bridging between foundations and the ground floor by using edge insulation.

- Second-hand bricks, sand/lime blocks or dense concrete blocks made with secondary aggregate, laid in a lime or weak cement mortar onto the smallest concrete strip necessary. Limecrete made from hydraulic lime and ballast, possible with additional pozzlan (setting) material.

- Concrete blocks made from new aggregate, or new bricks, laid onto the smallest concrete strip necessary.

- Trench-fill or reinforced concrete slab made from new aggregate. Short piles with reinforced concrete ground beams.

Timber construction:

- Timber (ground) beams spanning between timber piles or recycled brick piers on compacted re-used rubble. DPCs and membranes of recycled polythene or bitumen or slate.

- Piers as above on minimal concrete foundation. Posts set directly on a minimal concrete pad or short piles.

- Strip foundations and plinth wall as for masonry construction.

- Trench-fill or reinforced concrete slab made from new aggregate, unless ground conditions dictate. Short piles with reinforced concrete ground beam.

At CAT we avoid using cement-based mortar, render, concrete and blocks – mainly as a way to reduce embodied energy and carbon emissions. In many cases, cement materials are over-specified and can be replaced with lower impact materials. We have used lime-based render, mortar and concrete in a number of projects, as well as clay plasters. Instead of concrete block construction we’ve built with unfired earth, hempcrete, straw or other materials.

About half of the carbon dioxide (CO2) emissions from cement production are given off by a chemical reaction when limestone is heated to create cement. Most of the remaining CO2 emissions are from the fossil fuel used to fire cement kilns to high temperatures.

In the production of lime products, CO2 is still given off from a chemical reaction in the kiln. However, unlike cement, pure lime products reabsorb all of that CO2 as they dry out and harden over a number of years. A practical advantage of this slow setting is that it can usually be re-worked up to 24 hours after application (unlike cement or gypsum). It can also self-repair any small cracks that appear immediately after applying.

A hydraulic lime made from limestone with certain impurities will give a quick chemical set similar to cement, followed by slow carbonation. That process still reabsorbs a large proportion of the CO2 from the chemical reaction during manufacture. Hydraulic lime is useful as a binder in hempcrete construction, or in foundations.

Lime can absorb and hold moisture in periods of high humidity, and then release this moisture when the humidity levels drop. This helps to prevent condensation in interior spaces (the main cause of moulds and fungi).

Lime has advantages with conventional masonry construction as well. Bricks and stones joined with lime based mortar or render will separate and clean up, ready for re-use. It’s very difficult to separate bricks joined with cement mortar, so their only practical reuse is as hardcore.

Where the greater strength of a cement-based material is needed, the impact can be reduced by using an alternative such as pulverised fuel ash (PFA) or GGBFS (ground granulated blast furnace slag) to replace a proportion of cement used. GGBFS is a byproduct of the steel and iron industry, and PFA is waste from power stations.

The properties of lime must be well understood – it cannot be used in exactly the same way as cement. Accurate batching is critical, as is minimal and carefully administered water content. The mixing time is longer than for cement (10-15 minutes), but overmixing can turn the whole thing to jelly. ‘Limecrete’ must be protected from drying out too quickly (damp hessian is a favoured covering material) and it is essential to protect from frost for the first week or so.

Here are some options for floor construction from CAT’s eco-building experts.

A ground floor could be either of these:

- A suspended, well-insulated timber floor of homegrown soft or hardwood joists and floorboards. Good draught-proofing of the floor and ventilation of the underspace are vital. The underfloor space sealed with a recycled polythene membrane and covered in local granular fill or recycled aggregate.

- A solid limecrete floor using recycled aggregate, laid on insulation. Lime can be used to stabilise earth or hemp as a floor base and finish, but should not be covered with an impermeable material (such as linoleum). A damp-proof membrane of polythene or bitumen.

These are in preference to concrete (joists and slab, with plastic foam insulation) or chipboard (above concrete slab, etc).

For an intermediate floor, the first preference is for homegrown soft or hardwood tongue-and-groove timber floorboards on homegrown softwood joists with timber lath & lime plaster or plasterboard underlining. The second preference is for a similar method but with plywood board or OSB (oriented strand board) floor. Either is preferable to a concrete beam and block floor or chipboard.

Timber flooring is sustainable as long as new trees are planted to replace those that are used. The best guide at present is the FSC certification mark, which shows that the wood has been sustainably harvested. Most flooring is of hardwood (from deciduous trees), but some ‘softwood’ (from evergreens) can be more durable than some hardwood, so could be suitable for flooring.

Another sustainable option is reclaimed timber flooring, which could come from old schools, chapels, etc. You could look for local suppliers of salvaged/reclaimed materials, or use websites such as www.salvo.co.uk or www.communitywoodrecycling.org.uk

In their natural cycle trees absorb carbon dioxide during their lifetime and this is released as the wood rots away (or is burnt). By using wood in buildings we lock up this carbon and prevent it from re-entering the atmosphere.

Related Pages

Related events

Making Pallet Furniture (Only one place left)

18th May 2024

Build a Tiny House (Only one place left)

31st May 2024

Eco Refurbishment

3rd June 2024Study at CAT: Our Postgraduate Courses

Related news

Understanding insulation

10th December 2023

Short course spotlight – Renewables for Households: Heat Pumps

11th April 2023

Short course spotlight: Fixing your damp house

27th October 2022

Get warmed up to install a heat pump

17th August 2022Related Book

WANT TO LEARN MORE?

Did you know we are a Charity?

If you have found our Free Information Service useful, why not read more about ways you can support CAT, or make a donation.

Email Sign Up

Keep up to date with all the latest activities, events and online resources by signing up to our emails and following us on social media. And if you'd like to get involved and support our work, we'd love to welcome you as a CAT member.